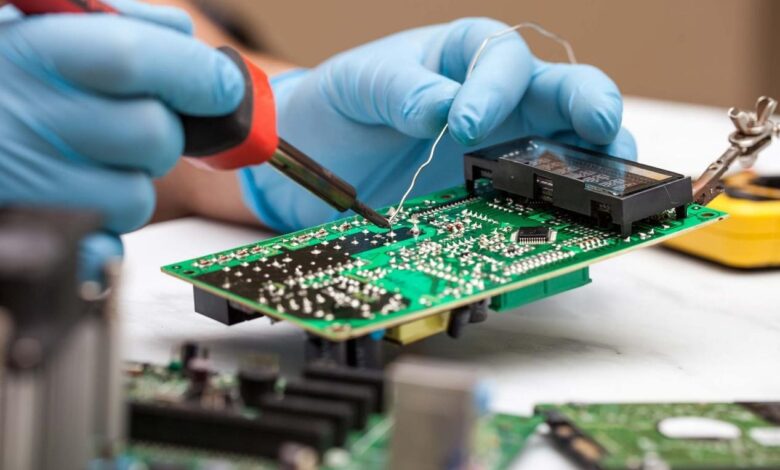

Complete Turnkey PCB Assembly Solutions for OEM Engineering Teams

In today’s fast-paced electronics market, OEM engineering teams face constant pressure to deliver innovative hardware under tight schedules and budgets. Managing multiple vendors, ensuring component quality, and maintaining seamless communication across design and production stages can quickly become overwhelming. That’s where turnkey PCB assembly solutions come in—streamlining procurement, manufacturing, and testing into one cohesive process.

OEM Engineering Challenges

Modern OEM teams often juggle several moving parts: component sourcing, supplier coordination, design verification, and testing. With traditional multi-vendor setups, communication breakdowns and logistical delays are common. Every misaligned timeline or misplaced component can add days—or even weeks—to a production cycle. As electronic designs grow more complex, with HDI and multilayer boards becoming standard, these inefficiencies can directly affect both cost and time-to-market.

What Turnkey Assembly Solutions Mean

Turnkey PCB assembly solutions offer a unified model where a single partner handles every step—from PCB fabrication and component sourcing to assembly and functional testing. Instead of managing multiple vendors, OEMs collaborate with a single integrated service provider that owns the full production workflow. This approach not only simplifies project management but also provides complete visibility into timelines, quality control, and engineering revisions.

Compared to basic contract manufacturing, integrated turnkey PCB assembly provides higher efficiency and accountability. All design files, BOMs, and revisions flow through one streamlined process, minimizing miscommunication and manual oversight.

See also: Unlocking Online Success: Why SEO Audit and Technical Optimization Matter in 2025

Procurement Benefits

Procurement is one of the biggest time sinks in hardware development. Traditional sourcing requires reaching out to multiple distributors, checking stock levels, and tracking part deliveries. In contrast, turnkey partners maintain established supply chain networks with trusted component vendors. They can secure components faster, verify authenticity, and avoid shortages through real-time inventory management.

For OEMs, this translates to reduced administrative workload and predictable cost control. There’s no need to coordinate between purchasing teams and assemblers—the turnkey provider manages it all under one purchase order.

Zero Cross-Vendor Communication

One of the standout advantages of turnkey PCB assembly is the elimination of cross-vendor communication. When fabrication, assembly, and testing are handled under a single roof, there’s no finger-pointing between suppliers. Any design clarifications or DFM (Design for Manufacturability) feedback are handled internally and delivered instantly.

This integration reduces waiting time, prevents data mismatches, and ensures all revisions are implemented correctly across every stage—from Gerber preparation to final inspection.

Engineering Review Benefits

With turnkey assembly, engineering teams gain valuable technical support through DFM, DFA (Design for Assembly), and DFT (Design for Testability) reviews. These reviews identify potential issues before fabrication, such as trace-width limitations, solder-mask clearances, or component-placement conflicts.

A proactive engineering review process minimizes rework and allows OEM teams to iterate faster with higher confidence in product reliability. This is especially important when scaling from prototype to production, where errors can multiply quickly if not caught early.

Faster Production Timelines

By consolidating fabrication, sourcing, and assembly into a single workflow, turnkey PCB assembly solutions for OEM engineering teams can significantly reduce production timelines. Lead times shrink as parallel processes—such as part sourcing and board manufacturing—run concurrently.

For fast-paced product cycles or urgent project milestones, this efficiency can make the difference between being first to market or falling behind competitors. OEMs can move from design submission to working boards in days, not weeks.

FastTurn PCB Capabilities

Among industry leaders, FastTurn PCB stands out for its comprehensive and high-precision turnkey services. From prototype development to full-scale production, FastTurn offers complete in-house fabrication, SMT assembly, and testing in accordance with strict ISO and IPC standards.

Their experienced engineering team provides detailed design feedback, helping OEMs optimize layouts and reduce cost per iteration. With global sourcing networks and rapid turnaround capabilities, FastTurn PCB ensures consistent quality and delivery reliability for both startups and established manufacturers.

Conclusion

For OEM engineering teams seeking speed, reliability, and reduced operational friction, turnkey PCB assembly solutions represent the most efficient production model. By centralizing communication, procurement, and engineering review under one expert provider, companies gain a competitive edge in both time-to-market and product quality.

Partnering with FastTurn PCB allows engineering teams to focus on innovation—while trusting that every PCB is built to exacting standards, on time, and on budget.