HDI PCB manufacturing – From Design to Delivery: FastTurnPCB Turnkey Solutions

In today’s fast-moving electronics industry, speed, precision, and reliability are no longer optional—they are essential. Companies need a PCB partner that can manage everything from early-stage design support to final product delivery without delays or quality risks. This is where FastTurn PCB stands out. With fully integrated turnkey solutions, FastTurnPCB simplifies the entire PCB lifecycle, ensuring seamless execution from concept to completion.

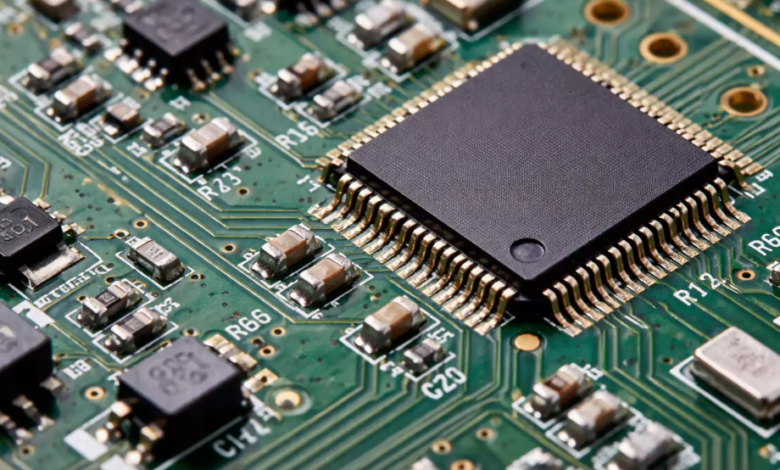

Understanding Turnkey PCB Solutions

Turnkey PCB solutions mean that a single provider handles every step of the process. Instead of coordinating with multiple vendors for fabrication, assembly, component sourcing, and testing, customers work with one trusted partner. FastTurnPCB’s turnkey services eliminate complexity, reduce errors, and significantly shorten production timelines.

By combining engineering expertise with advanced hdi pcb manufacturing, FastTurn PCB ensures that even the most complex designs are produced efficiently and accurately.

Design Support and Engineering Expertise

A successful PCB project starts with a solid design. FastTurnPCB offers engineering support early in the development phase to help customers optimize layouts for manufacturability and performance. This proactive approach helps identify potential issues before production begins.

Design-for-Manufacturability (DFM) and Design-for-Assembly (DFA) checks ensure that boards are compatible with advanced HDI PCB manufacturing processes. This not only improves yield rates but also reduces costly revisions later in the project.

Advanced PCB Fabrication Capabilities

FastTurn PCB provides a wide range of fabrication services to support diverse applications. These include:

- Single-layer and multilayer PCBs

- High-density interconnect (HDI) boards

- Rigid, flexible, and rigid-flex PCBs

- High-frequency and high-speed PCBs

With state-of-the-art equipment and strict process controls, FastTurnPCB delivers consistent quality across both prototype and production volumes. Their expertise in HDI PCB manufacturing enables finer trace widths, microvias, and higher layer counts required by modern electronics.

Component Sourcing Made Simple

Component sourcing is one of the most challenging aspects of PCB production, especially in a volatile global supply chain. FastTurnPCB handles this complexity by leveraging a trusted network of authorized suppliers.

FastTurn PCB ensures that all components are genuine, traceable, and compliant with industry standards. By integrating sourcing into their turnkey model, they reduce lead times and prevent compatibility issues during assembly.

Precision PCB Assembly Services

Once fabrication and sourcing are complete, FastTurnPCB moves seamlessly into assembly. Their assembly services include:

- Surface Mount Technology (SMT)

- Through-hole assembly

- Mixed-technology assembly

- Fine-pitch and BGA placement

Advanced inspection systems ensure accurate placement and soldering, even for boards produced using HDI PCB manufacturing techniques. This level of precision is critical for high-performance and mission-critical applications.

Rigorous Testing and Quality Assurance

Quality assurance is a core part of FastTurnPCB’s turnkey solutions. Every assembled PCB undergoes comprehensive testing to ensure performance, reliability, and compliance.

Testing services include:

- Automated Optical Inspection (AOI)

- In-Circuit Testing (ICT)

- Functional testing

- Burn-in testing

These processes help identify defects early and ensure that only fully functional boards reach the customer. FastTurn PCB’s commitment to quality makes them a reliable partner for industries with strict standards.

See also: Unlocking Online Success: Why SEO Audit and Technical Optimization Matter in 2025

Fast Turnaround Without Compromising Quality

Speed is a defining advantage of FastTurnPCB. Their integrated turnkey model eliminates unnecessary handoffs, allowing faster transitions between design, fabrication, and assembly.

Even for complex projects involving HDI PCB manufacturing, FastTurn PCB delivers rapid turnaround times while maintaining strict quality control. This allows customers to meet aggressive launch schedules and stay competitive in their markets.

Serving Multiple Industries

FastTurnPCB’s turnkey solutions support a wide range of industries, including:

- Consumer electronics

- Medical devices

- Automotive systems

- Industrial automation

- Telecommunications

Each industry has unique requirements, and FastTurn PCB adapts its processes to meet specific performance, reliability, and regulatory needs.

Cost Efficiency Through Integration

Managing multiple vendors often leads to hidden costs and inefficiencies. FastTurnPCB’s all-in-one turnkey approach reduces administrative overhead, minimizes errors, and improves cost predictability.

By optimizing workflows and leveraging economies of scale, FastTurn PCB delivers cost-effective solutions without sacrificing quality—even for advanced HDI PCB manufacturing projects.

Transparent Communication and Project Management

Clear communication is essential for successful project execution. FastTurnPCB provides regular updates, clear timelines, and responsive support throughout the production process.

Dedicated project managers ensure that customer requirements are met at every stage, from design review to final delivery.

From Prototype to Mass Production

Whether customers need a single prototype or large-scale production, FastTurnPCB scales its services accordingly. Their turnkey model ensures consistency and reliability across all production volumes.

FastTurn PCB’s ability to transition smoothly from prototyping to mass production makes them an ideal long-term manufacturing partner.

Why Choose FastTurnPCB Turnkey Solutions?

Companies choose FastTurnPCB because they offer:

- End-to-end turnkey PCB services

- Advanced expertise in HDI PCB manufacturing

- Fast and reliable turnaround times

- Strong quality assurance processes

- Cost-effective and scalable solutions

These advantages make FastTurn PCB a trusted partner for complex and time-sensitive PCB projects.

Conclusion

From initial design to final delivery, turnkey solutions simplify PCB production and reduce risk. FastTurn PCB provides a complete, integrated approach that combines engineering expertise, advanced manufacturing, and rigorous quality control. With proven capabilities in HDI PCB manufacturing, FastTurnPCB empowers businesses to bring innovative electronic products to market faster and more reliably.

To learn more about their complete turnkey PCB services, visit FastTurn PCB.